The Art and Science of Chocolate

It’s a long way from the cacao-growing regions of the world to northern Utah. But cacao is making the trip from South and Central America to the newly opened Aggie Chocolate Factory, and students at Utah State University are learning first hand that the journey from cocoa bean to chocolate bar is no less dramatic than differences between Belize or Ecuador and Utah.

The College of Agriculture and Applied Sciences (CAAS) opened the Aggie Chocolate Factory in late 2018. Part teaching facility, part laboratory, and part café, the factory is an outgrowth of food science Professor Silvana Martini’s research in fats and sensory evaluation and the course she teaches each fall semester, Chocolate: Science, History and Society.

Josie Sorensen, a sophomore food science major from Gunnison, Utah, enrolled in the course having no idea chocolate making was so complicated or that working in a chocolate factory was in her future.

“People don’t understand what food science is,” Sorensen said. “Everyone thinks I want to be a chef, but I don’t. I want to be a food scientist, studying food’s components, systems of producing it and processing it, and my dream is to do humanitarian work focused on hunger issues. It is really fun when people come to the chocolate factory and café because I can tell them all about the process, the components, and explain flavor differences.”

Josie Sorensen (blue cap) and Annelise Burr are part of the Aggie Chocolate Factory team that is 100 percent student employed.

In addition to serving students in that course as a laboratory, the factory staff and college faculty will be doing research as new funding opportunities arise, and collaborations with chocolate and candy makers large and small are explored. CAAS Dean Ken White considers the factory a new tool for fulfilling USU’s mission to serve people and industries in Utah, including the state’s numerous candy companies and nearly a dozen artisan chocolate makers and chocolatiers.

Sources differ slightly on the amount of chocolate American’s consume on average each year, but agree on about 11 pounds, which is fully half of all the candy Americans consume, though 11 pounds doesn’t come close to the 22 pounds of chocolate consumed annually by Europeans. But all the chocolate in the world begins with the pods of cacao trees that can only be grown in countries within the narrow band 20 degrees north or south of the equator.

It starts with beans

“About 70 percent of cacao production worldwide is in Africa, and especially West African countries,” Martini says. “Growers there are quite poor, not well educated, and their cocoa beans are sold through governments where there is a lot of corruption. Cacao in West Africa begins in the hands of growers on more than two million small farms that are almost all family owned. Their yields are very low because they don’t have the knowledge to increase yields with best practices for caring for the trees and the soil.”

Hand-sorted cacao beans are roasted to perfection.

Those beans are bought by companies that make huge quantities of chocolate. The world’s top chocolate makers—including Barry Callebaut, Cargill, and Olam—make chocolate to sell to large candy makers that use it to create the confections we commonly see on store shelves. The chocolate makers are working to help farmers improve the health of their trees and recognize diseases before entire farms or harvests are lost. Martini adds that the companies are also building roads and schools, and teaching growers basic math and business skills, all in an effort to get ahead of predictions that in the near future there will be too little cacao being grown to meet demand.

As with most fruits and vegetables, cacao flavors are the result of a long list of variables, including different plant varieties, soils they are grown in, temperatures and weather, water sources and amounts, elevation, harvest time, and handling after harvest.

“For the mass market, you can’t have a bar of chocolate with fruity flavors one time and then have completely different flavors the next batch or the next year,” Martini says. “Big companies are looking for consistency and roast beans at higher temperatures to achieve it.”

Flavor variations in beans from different sources are prized though by small-batch, artisan chocolate makers, who typically buy cacao directly from growers or co-ops in South and Central America. Aggie Chocolate Factory Manager Steve Shelton says the factory is committed to purchasing fair trade cacao and organic sugar, cane sugar, because other sugars just don’t work well with chocolate.

“Our cacao from Belize comes from Maya Mountain Cacao and they work with more than 400 farmers and have increased the farmers’ income by more than 20 percent,” Shelton says. “But even more importantly, since Maya Mountain was founded (in 2010), the number of those farmers’ children who go to school has increased by over 85 percent.”

In addition to the chocolate produced from the Maya Mountain beans, the Aggie Chocolate Factory currently makes chocolate sourced from a family-owned, 100-hectare farm in Ecuador that is the “house chocolate” that goes into the cookies, brownies, and other confections sold in the factory’s café.

Shelton and Martini foresee the factory producing eight-to-10 single source chocolate bars with beans from several countries. Even now, with just two in-house bars to compare, the differences in flavor are striking. The cacao from Belize produces a bar that first releases flavors likened to berry or pineapple as it melts on your tongue and then finishes with what Shelton calls “a little kick to remind you that this is a very dark chocolate.” The Ecuadoran chocolate maintains a good, straightforward flavor similar to a dark brownie batter. Both bars are made from just two ingredients, organic cacao and sugar, and most steps in the long process are the same.

Flavor is perfected

Developing distinctive flavor profiles while roasting and processing the beans is where art meets science in artisan chocolate making. But it’s a long process from bean to bar, and parts of it beg the question, “Who on earth looked at a cacao pod and thought of doing this in the first place?”

The short answer is the Olmecs, whose complex civilization along the Mexican Gulf Coast thrived from 1500–400 B.C., but whole volumes have been written about the history of chocolate. Students in Martini’s chocolate course get to try their hands at grinding cacao and blending it with hot water to make a drink that was prized by Olmecs and later civilizations in the New World. It’s a good experience, but the bitter drink is a long way from the sugary, creamy hot cocoa drinks students are used to and not likely to win over even devoted lovers of dark chocolate.

Almost to yum.

“The Olmec drink was awful,” Sorensen recalls. “None of us could imagine how the chocolate we know could have come from that. Now when I have chocolate, I really appreciate it and I’ve become a bit of a chocolate snob.”

Chocolate begins with pods from cacao trees that are vibrant shades from green to red. The pods are opened sometimes by machete, sometimes with other tools (including baseball bats), to reveal a fibrous, white, slimy pulp surrounding rows of large seeds. Shelton describes the pulp as similar to a delicious fruit smoothie, “but the texture is really not pleasing.” The beans, which are actually seeds, and pulp are put in wooden boxes or on the ground on top of banana leaves where the sugars in the pulp are broken down through a fermentation process. The beans are moved through a series of boxes, or stirred with a shovel when fermentation occurs on the ground, until the white pulp disappears. The fermented beans are then spread on a platform and left there to dry.

Dry beans are hand-sorted, bagged, and shipped worldwide, but their path to being transformed into chocolate is just beginning. When bags of cocoa beans arrive at the Aggie Chocolate Factory, they are put in a freezer set at 0° F and kept there for two weeks to kill any diseases, mold, or insects that may have made the trip. At the end of two weeks, the beans are moved to a walk-in cooler at about 42°F for a week, and then to the sorting room which is kept at a cool 61°F so the beans gradually warm and condensation that could cause mold does not form. The factory’s small team of student workers sort the beans by hand, removing any pebbles, twigs, broom bristles, or other non-cacao items and any beans with broken shells.

“If we put a cracked bean in the roaster it will get ultra-roasted in relationship to the other beans and it would bring a lot of very dark flavor to that batch of chocolate,” Shelton explains. “Each batch of sorted beans for the roaster in our small facility is about 11 pounds, and six batches from the roaster go on to become one batch of chocolate.”

But the beans’ transformation is still far from finished. Each batch is in the roaster for 25-30 minutes to develop the beans’ unique flavors, then into a cracking and winnowing machine to separate the shells from the cocoa nibs. The nibs are put in a pre-refining machine with two rollers made of stone that break the nibs to bits about twice the size of a typical sugar granule. From there, 11 pounds of nibs at a time are poured into the cutter mixer that is like an industrial strength food processor, where the heat produced by the friction of the spinning blades causes fat in the nibs to melt and create a slurry known as cocoa liquor.

“It is a consistency a little thinner than peanut butter and it’s extremely bitter,” Shelton says. “If I had been inventing chocolate, I would have gotten to this stage and said, ‘I’m done. Nothing good can come of this.’”

And finally, chocolate

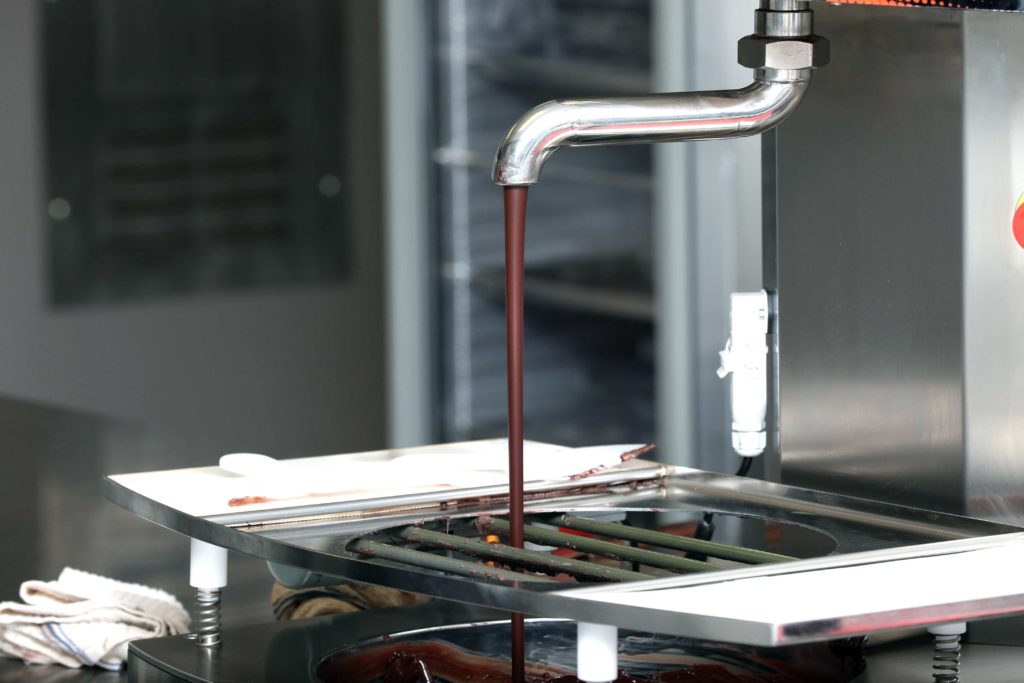

Fortunately, someone in history pushed past that unappealing phase, but there are still more steps in the process. The cocoa liquor is put in a press and cocoa butter is excreted and captured, while the solids become hard disks of cocoa powder. That powder then goes to a grinder, or melanger, where stone wheels roll over it continuously for six days.

Shelton says the point is to grind it so finely that your tongue can’t perceive individual granules that would make it feel even the least bit gritty. At the right time during this grinding process sugar and other ingredients are added. Yes, the timing of when sugar is added also changes the flavor profile even when you begin with the same batch of cocoa liquor. Then the chocolate is aged to let flavors develop further, re-melted, and tempered to allow for cocoa butter to form the right crystals and finally, chocolate is poured into molds, taken to a cooler to allow hardening, then hand-wrapped in foil, and packaged.

Small batch, stone-ground, hand-crafted deliciousness.

Sorensen says in labs for the chocolate class, small groups of students made chocolate using different processes and fats. In the end, they made 12 different chocolates from bean to bar with very distinct flavors and textures for a side-by-side tasting.

Bars of chocolate currently at the factory are 70 percent cacao and 30 percent sugar. That’s it. No other ingredients. But it’s far from simple because each recipe—which includes every step from roasting to being poured into molds—will have to be adjusted with each new harvest. Even though cacao will be coming from many of the same sources year after year, each harvest will have slightly different flavors because growing and harvest conditions will never be exactly the same.

Martini points out that a defining characteristic of cocoa butter is that it melts very fast in your mouth.

“Fast melting allows flavors to be released,” she says. “So when you eat a piece of chocolate, especially an expensive piece, you don’t want to swallow it quickly. You want to hold it on your tongue, let it melt, breathe to allow those aromas to travel from your mouth to your nose and try not to chew it too much. You want to give it time to melt in your mouth, not in your throat or your stomach.”

Each bar of Aggie Chocolate is hand wrapped.

Sorensen loves telling potential customers about chocolate and offering tastes, but has found many just won’t try it because they are certain they don’t like dark chocolate.

“Some of them say, ‘I’ll just have hot chocolate,’ and I have to warn them this is not your American style hot chocolate mix and some hot water. Our sipping hot chocolate is dark and so rich that if you refrigerate it, it will solidify. But it’s fun when someone orders it and really appreciates it.”

As the Aggie Chocolate Factory becomes more established and students and faculty experiment with processes and products, expect more varieties of dark chocolate, milk chocolate, Aggie Chocolate in Aggie Ice Cream, tasting events, and educational opportunities. This summer the factory will host its first week-long short course for people in the industry, and shorter workshops for home candy makers are expected to follow.

“It will be exciting to see what we will create with our students when we’ve been up and running for more than just a few weeks,” Martini says. “I tend to like very simple chocolates more than chocolate with a lot of other things mixed in. Actually, I need to rework that sentence. I really love all chocolate.”

To learn more about the Aggie Chocolate Factory go to www.aggiechocolate.com.

By Lynnette Harris ’88

Glossary of Chocolate

Cacao: Raw materials—trees, pods, beans, cocoa liquor—for making chocolate, cocoa powder and cocoa butter. Technically, cacao and cocoa are interchangeable, but the industry tends to use “cacao” to mean raw ingredients and “cocoa” to describe processed elements like cocoa powder and cocoa butter.

Cocoa liquor: A dense, dark, chocolate liquid created by finely grinding roasted cocoa nibs. It contains no alcohol, but refers to the liquid state the nibs are in as they are ground. It may also be referred to as cocoa mass and chocolate liquor.

Chocolate maker: Person or company that produces chocolate by processing dried cocoa beans.

Chocolatier: Person that uses chocolate produced by a chocolate maker to create confections, which may be chocolate bars, enrobed candy centers, truffles, etc.

Jessica May 8, 2019

It is really great article. Thank you for posting. I do not know how first people started making chocolate but it the most lovely thing human beings made.